The United States has not fought a symmetric war of front lines and maneuver since Korea. From then on our actual opponents have not had artillery, tanks, or attack aircraft for more than a few days. Symmetric warfare has been replaced by asymmetric warfare with the enemy using small arms, IEDs, and infiltration in Southeast Asia, Africa, the Balkans, and the Middle East. The current response involves fortified bases with cleared fields of fire and targeted operations launched from those bases. While night vision technology gives US tactical forces a big advantage at night, illumination of the base surroundings makes infiltration harder and aids target identification by troops without NVDs. The main problem is that conventional spotlights and searchlights are both fire magnets and extremely vulnerable to ordnance. While economical and very useful for general surveillance, conventional lights can be taken out by snipers at the start of an attack and need to be backed up by something more resistant to small arms that can reasonably survive a short firefight. Small arms resistance should be sufficient as heavy weapons like artillery, tanks, and attack aircraft will have already been taken care of by the Air Force. Also it should be possible to keep RPG teams beyond effective range with an adequate field of fire and enough light. Conventional spotlight weaknesses fall into two categories. Reflector surfaces are often silvered glass which shatters at the first hit. A tougher reflector directs ricochets toward the light source, be it a light bulb, arc electrodes, or LED’s which are all easily destroyed by small arms projectiles or shrapnel. “Bulletproof” glass is not very effective here as high velocity hits will craze it, reducing illumination, and ultimately break through, especially 12.7mm rounds.

The only light source which is truly bulletproof is an illuminating gas flame. Properly armored reflectors and burners could provide a robust back-up to conventional lighting. A typical illuminating gas would be acetylene burned in air which produces a bright white light. Acetylene is readily available and is a normal part of the military supply chain. Alternately, acetylene could be produced by generators at the light by reacting calcium carbide with a controllable water source. Other illuminating gas mixtures could be optimized for the application. Acetylene has been used for some lighthouse lamps from 1896 to the present.

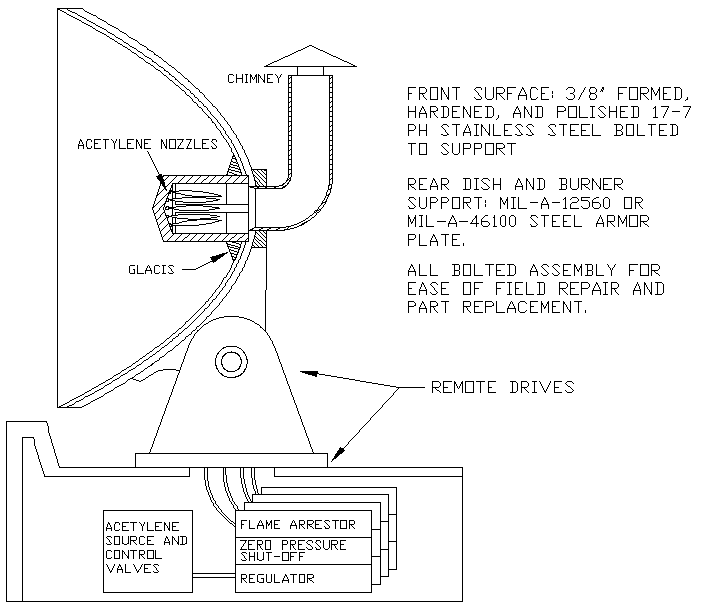

The illustration is for an acetylene tank version with a 3 foot diameter dish. A carbide version could mount the generators on the back of the dish and eliminate the gas controls except for water shut-offs.

Since any light will be a fire magnet, it is critical that this be remotely operated with perhaps a covered manual override. The tank is installed below grade or certainly under RPG proof cover. The idea is to provide four redundant gas channels with separate nozzles, fed through unions in the pitch pivot. The control modules consisting of the flame arrestor, regulators, and control valves for each channel would reasonably be mounted in the turret and move with it. Each channel and the main tank would have a zero back pressure shut-off valve so that if a line is severed, flow to that line automatically shuts off. A possible reflector would be 3/8″ of 17-7 PH stainless steel formed to the desired profile, hardened, and polished to a mirror finish. This would be bolted to a curved backing plate giving full support made out of armor plate. The plate would be bolted to the pitch/yaw mechanism. The burner head would bolt to the mount and contain four separate o-ring sealed passages running between receivers in the mount and the burner nozzles. Like all parts this would be a plug-in, bolted assembly to facilitate field repairs. Flame ignition would be electrical or possibly catalytic depending upon gas choice. A rear mounted chimney of a refractory material would direct the gas exhaust up and away from the mechanism. This would avoid darkening the reflector with soot and spilling light onto the defenders. The top of the burner assembly would have a sufficient thickness to resist small arms and have a conical top to deflect ricochets away from the dish surface. Ricochets from the main part of the dish would pass though the flame without effect. Near the center, a glacis would deflect shots safely that would otherwise ricochet into the gas nozzles. The redundant gas channels and auto shutoffs would allow the spotlight to continue operating after losing nozzles. The illustration is scaled for 7.62×39 but could easily be adapted for heavier weapon resistance.