One shortcoming of older small lathes is the lack of a carriage travel calibration unlike on the cross slide. An X-axis DRO solves this problem but they are not made specifically for older lathes and are often difficult to adapt as the bed and saddle castings did not envision them. The compound may be used for small, precise X-axis moves but the travel is limited and the compound angle must be indicated in for accurate work. Older lathes like the Atlas/Craftsman do not have a parallel surface on the compound which makes this quite difficult. When using the milling attachment which does have a Z-axis dial, there is no alternative as it replaces the compound. The simplest solution is to use a 1″ or 2″ dial indicator but it is often difficult to mount appropriately using regular indicator holder hardware. Here is a simple, inexpensive solution:

An adequate magnetic base is under $16 at Amazon or Shars. The rest of this can probably come from your scrap bin.

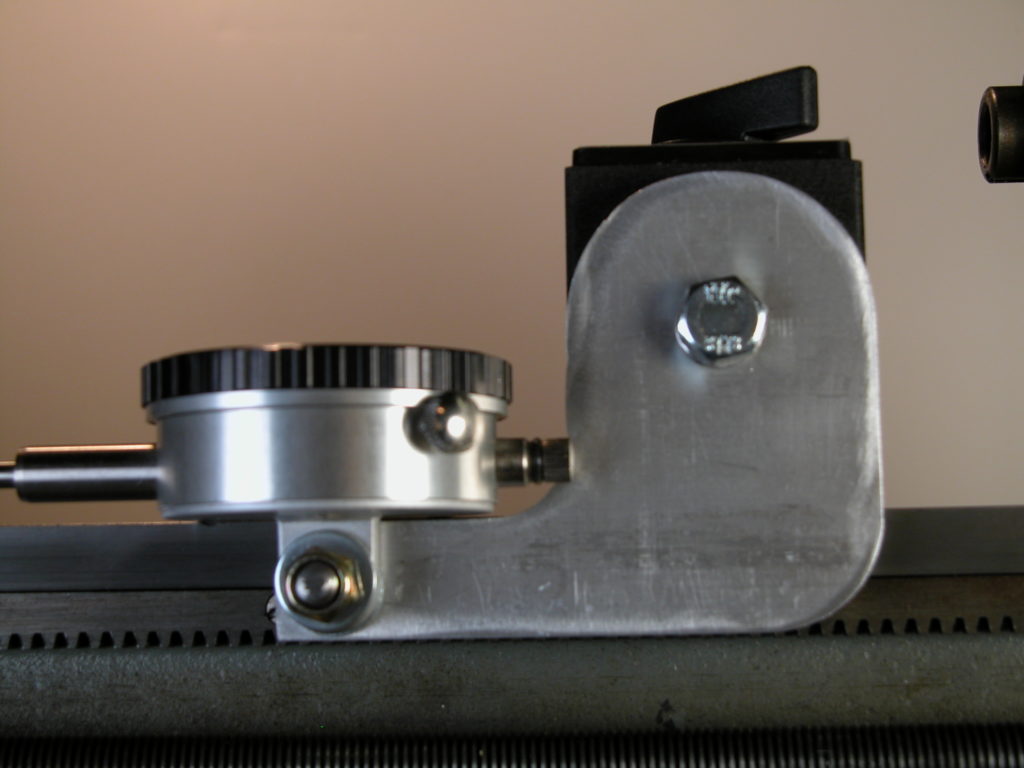

This is simply an “L” shaped piece of 1/4″ aluminum with an 8mm hole for the bolt and washer attaching it to the magnetic base and a pinned-in 1/4″ stud to attach and tension the indicator with a nylon lock nut. The back of the stud is flush with the back of the plate. In addition to the washer under the nut as shown, there is another washer on the stud under the indicator to provide clearance for the plunger travel past the vertical plate. Note that the narrow leg is about 1/16″ below the bed so the indicator can sit squarely to be aligned with the carriage travel. This design works best on flat bed lathes like the Atlas series but can be adapted to others.

The spambots are getting out of hand : Please leave comments using the post in my comments category. 🙂